Beam Me Down, Scotty

It is clear that what is invented for space travel and exploration can spawn industries back on Earth.

Back in the 1970s, contemporary research was looking at what was space-based solar power. The idea was to send satellites into space to generate electricity and then beam the power so generated back to Earth.

Nearly half a century later, space-based solar power is no longer just a concept. Numerous countries have spent time and money towards developing a working prototype. While some are focusing on launching a heavy payload into space for the purpose, others are looking at storing the energy generated and some are researching the most important part – bringing that electricity back to Earth.

The Japan Aerospace Exploration Agency (JAXA) figured that among the various proposals, including electromagnetic induction and carbon nanotubes, the most feasible way to beam electricity down from outer space would be through using microwaves. The reason behind it was simple – the short frequency of microwaves allows them to transmit a large amount of power.

JAXA partnered with Mitsubishi Electric to work on microwave transmission, and in 2015 successfully managed to transmit 10 kilowatt of power over 500 metres. Subsequently, Mitsubishi decided that this breakthrough could have other uses as well and announced that they intended to use the method to ‘beam’ electricity for myriad purposes, from power supply to charging electric vehicles (EVs).

This isn’t the first time that research meant for outer space found applications back on Earth. The United States’ National Aerospace and Science Administration (NASA) has earlier developed numerous products meant for the International Space Station (ISS) that are today used in mainstream applications globally.

An eye-tracking device to help prevent disorientation has found its way to mainstream corrective laser surgeries. Algae-based additives used in food for outer space found its way to baby food. Remember the ready-to-eat meal that just requires adding hot water? That too was a result of figuring out a way to keep food with its nutrition intact in outer space. A system to provide filtered water aboard the ISS is today used to provide potable water in under-developed nations. Fire-resistant fabric too has similar origins.

Looking At Space With A Commercial Vision

Space has traditionally been used for communication and intelligence purposes so far, mostly using satellites. But now, countries are looking at getting the most out of the vast universe. China has even proposed exploiting the ‘Earth-moon space for industrial development’. The concept of commercially exploiting space itself though is not new and has consistently thrown up new and interesting ideas. The most well-known of these is that of asteroid mining. Asteroids in outer space are loaded with minerals that many countries are looking to mine. Among the minerals are valuable ones including, gold, platinum, tungsten, palladium and silver. Apart from these, there are other minerals such as titanium, aluminium and manganese that can be used for construction.

Elon Musk Ventured There Too

American inventor and entrepreneur Elon Musk, as part of his firm SpaceX’s mission to colonise Mars, announced the Big Falcon Rocket (BFR) in 2015. A component of his proposed interplanetary transport system, the fully-reusable BFR’s main role would be to provide transportation between the Earth and other planets while also offering rapid launch and relaunch capabilities to put payload into outer space.

However, in 2017, Musk proposed that the BFR be used for Earth-to-Earth spaceflight. He said that he envisioned a journey from Delhi to Tokyo that could be done in a mere 30 minutes. What’s Musk’s rationale behind the idea? Low-cost connectivity in record time could help the company earn revenues that it can then repurpose for its actual space research.

Space Research Includes Batteries Too

The Indian Space Research Organisation and Bharat Heavy Electricals Limited this year announced a tie-up to manufacture space-grade lithium-ion (Li-ion) batteries in India. These batteries typically have a higher-storage density and longer life and are also capable of withstanding extreme conditions in outer space. Not just that, these batteries are slowly finding their way into commercial use and are expected to find greater applications in EVs back on Earth.

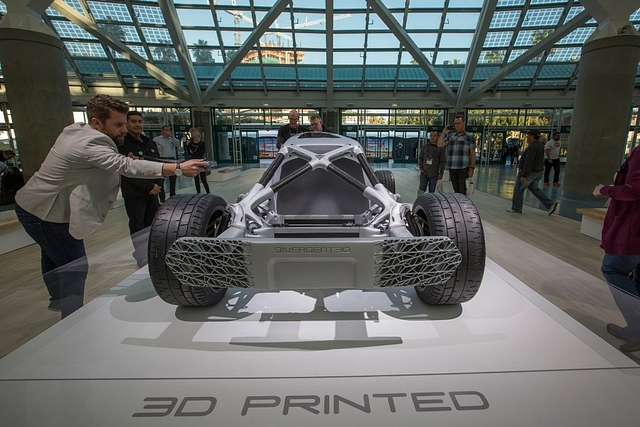

3D Printing

Ever since its inception, three-dimensional printing, or 3D printing, has been in the news for various reasons. Conceptually, it is appealing to many in the science sector to develop components that can be used ‘off-the-shelf’. Simply put, developers merely have to design the component and let the printer bring it to life.

NASA, in 2014, installed its first 3D printer aboard the ISS, using it to print various components required, starting with an extruder plate. The objective behind going for 3D printing is basic economics – why spend millions of dollars to send a rocket with spare parts to space when they can be printed locally? Note that the SpaceX Falcon 9 costs $62 million per launch, while NASA spends $1.5 billion for a space shuttle mission. Of course, the raw material required, be it plastic or metal would need to be stored out there, but storing bulk material is always more economical in terms of space occupied than specific components. NASA estimates that about 30 per cent of its components could be printed in the ISS itself. The agency is also looking at printing CubeSats using these printers to deploy them from the ISS rather than from the Earth, thus reducing their components drastically.

But Why Is 3D Printing So Crucial?

NASA was assisted in its 3D printing objectives by a start-up named ‘Made In Space’ that says 3D printing combined with space mining can help the human race in its mission to colonise outer space. The firm says that outposts for humans can be printed using raw material mined from asteroids and even the moon or Mars.

But the process isn’t limited to just components. NASA, in 2013, awarded a research grant to develop a 3D food printer, with a firm called BeeHex finally developing a 3D pizza printer for outer space. That’s right, pizzas being printed at the click of a button. Such systems can help humanity in various situations such as providing food for malnourished children in poorer countries and helping soldiers during war.

Outer space, due to its rather delicate nature poses a plethora of unique situations. Lack of gravity, risks associated with space debris and other dangers make it important for all printed components to be extra durable.

This brings us back to Earth. 3D printing down here is being explored for various purposes including construction and transport.

Companies globally have been shifting from erecting a building entirely on site to using prefabricated components. These components are cast elsewhere, and then shifted to the site where they are assembled. A good example of this would be construction of bridges, especially for metro rail systems, where the girders are cast ex-situ and then raised onto the pillars using a gantry crane to form the viaduct.

While cities such as Dubai have gone ahead in setting up printed office spaces and aim to construct printed skyscrapers as well, the scenario is still nascent. Firms in New York are planning to use 3D-printed ‘pods’ that stack atop each other to create shelters for the homeless while a park in Madrid, Spain, houses a 3D-printed bridge.

Due to the fragile conditions in outer space, any development in the technology that works in outer space will be more durable back on Earth, where conditions are more favourable. As research accelerates, the space race will act as a catalyst in increasing the demand that will in turn lower their prices. The cost of such improved technology back on Earth will be a fraction of what it costs in outer space. The materials used in a 3D-printed satellite that is impervious to damage from solar flares and debris can be used in making buildings damage-proof and also help with climate-controlled homes in tropical nations. These printing technologies can subsequently be used to build other structures too. Imagine long-pending metro projects being completed in nearly no time due to sturdy and durably printed prefabricated components.

But that’s not all. 3D printing is also making its foray into the transport sector. The Olli, built by Arizona-based Local Motors, is an autonomous, air-conditioned electric minibus that is 3D printed. It commenced operations in Washington DC back in 2016 and uses IBM’s Watson learning platform to operate using the Internet of Things.

Conditions in space have helped us research better products that function even better back on Earth. Imagine, an entire city getting a 3D-printed elevated metro line in a matter of months with the trains being 3D printed too! It would be cost effective and save time, allowing better commuting standards.

The research may be intended for outer space, but find multi-purpose usage back here on Earth.