Business

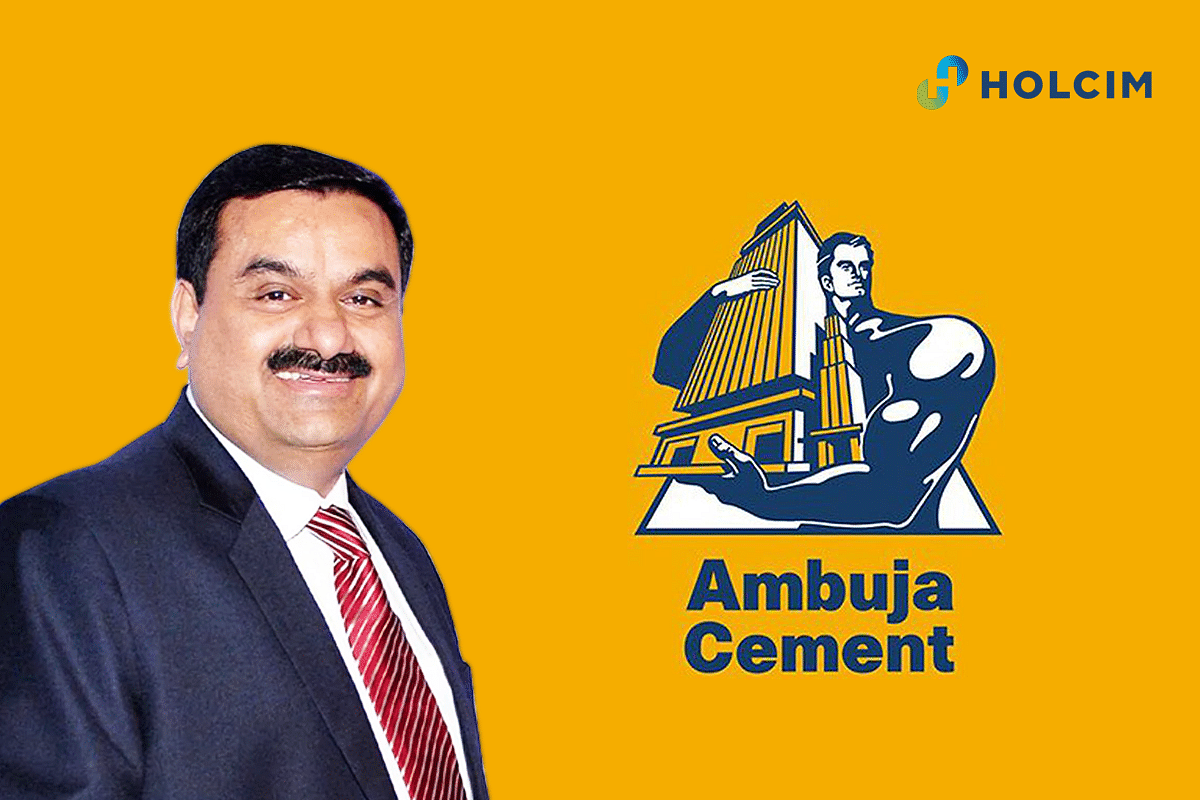

Explained: Adani's $10.5 Billion Ambuja Cement-ACC Acquisition

- Adani Group is a diversified organisation in India with a market cap of over $183.69 billion, comprising seven publicly traded companies.

- The Adani-Holcim deal is the biggest-ever acquisition by Adani and also India's largest-ever merger and acquisition (M&A) transaction in the infrastructure and materials space.

Gautam Adani

The Gautam Adani-led Adani Group has acquired a controlling stake in Holcim AG's cement businesses in India in a $10.5 billion (Rs 80,000 crore) deal to become the second biggest cement producer in the country.

Holcim, through its subsidiaries, holds 63.11 per cent in Ambuja Cements and 54.53 per cent in ACC (of which 50.05 per cent is held through Ambuja Cements). The Adani family, through an offshore special purpose vehicle (SPV), has entered into definitive agreements for the acquisition of Holcim Ltd's entire stake in Ambuja Cements and ACC.

Significance of the deal

The deal is not just the biggest-ever acquisition by Adani, but also India's largest-ever merger and acquisition (M&A) transaction in the infrastructure and materials space.

The transaction is subject to approval by competition regulators and local authorities and is expected to close in the second half of CY22.

What explains Adani's foray into cement business?

Adani Group is a diversified organisation in India with a market cap of over $183.69 billion (as on 16 May 2022), comprising seven publicly traded companies. The infrastructure-to-energy conglomerate is involved in various sectors, including ports, power, renewable energy, infrastructure, food products and airports.

The acquisition is part of Adani group's plans to move beyond its core business of operating ports, power plants and coal mines, and into areas like data centres, airports, and infrastructure and materials space.

Gautam Adani, Chairman of the Adani Group, said: "Our move into the cement business is yet another validation of our belief in our nation's growth story. Not only is India expected to remain one of the world's largest demand-driven economies for several decades, but also continues to be the world's second largest cement market, and yet, has less than half of the global average per capita cement consumption."

"In statistical comparison, China's cement consumption is over 7x that of India's. When these factors are combined with the several adjacencies of our existing businesses that include the Adani Group's ports and logistics business, energy business, and real estate business, we believe that we will be able to build a uniquely integrated and differentiated business model and set ourselves up for significant capacity expansion," he added.

What does the deal mean for the Adanis?

The noted wealth manager, PhillipCapital, has described the deal as a “master stroke”.

Ambuja Cements and ACC currently have a combined installed production capacity of around 70 Million Tonnes Per Annum (MTPA). The two companies are the second and third largest players in the cement sector respectively, represented by their 23 cement plants, 14 grinding stations, 80 ready-mix concrete plants and over 50,000 channel partners across India.

The acquisition will add a 70.9 MTPA capacity of cement production and catapult Adani Cement as the second-largest cement maker in the country in one shot. The company will be next only to Aditya Birla group’s UltraTech Cement, which has a capacity of 120 MTPA.

The Adani group last year set up two cement subsidiaries - Adani Cementation Ltd, which was planning to set up two cement units at Dahej in Gujarat and Raigarh in Maharashtra; and Adani Cement Ltd.

Both Ambuja and ACC will benefit from synergies with the integrated Adani infrastructure platform, especially in the areas of raw material, renewable power and logistics, where Adani Portfolio companies have vast experience and deep expertise. This will enable higher margins and return on capital employed for the two companies.

The industry is now bracing for the Adani Group’s aggressive expansion in the cement industry and doesn't rule out the potential for more consolidation.

Where does India stand globally in Cement production?

Accounting for over 7 per cent of the global installed capacity, India is the second largest producer of cement in the world, second only to China.

It plays a binding and pivotal role in both the infrastructure and socio-economic development of the country; moreover, the Indian cement industry is the fourth-largest revenue contributor to the exchequer and the second-largest revenue contributor to the Indian Railways - it contributes nearly $7.14 billion (Rs 50,000 crore) per annum to government via taxes and levies, and about $1.29 billion (Rs 9,000 crore) per annum to the Indian Railways by way of freight revenue.

The Cement Manufacturing Association (CMA) currently estimates that India has an installed cement capacity of 545 MTPA. Of the total capacity, 98 per cent lies with the private sector and the rest with the public sector. The top 20 companies account for around 70 per cent of the total cement production in India. As India has a high quantity and quality of limestone deposits throughout the country, the cement industry promises huge potential for growth.

India’s overall cement production accounted for 294.4 million tonnes (MT) in FY21 and 329 MT in FY20 and is projected to reach 381 MT by FY22.

What is the extent of domestic consumption?

The cement consumption stood at 327 MT in FY20 and will reach 379 MT by FY22. The cement demand is estimated to touch 419.92 MT by FY 2027.

Rural housing demand and the government's strong focus on infrastructure development is likely to boost demand for cement. As per Crisil ratings, the Indian cement industry is likely to add almost 80 MT capacity by FY24, the highest since the last 10 years, driven by increasing spending on housing and infrastructure activities.

Is there any potential for capacity expansion?

With India’s cement consumption at just 242 kg per capita, as compared to the global average of 525 kg per capita, there is significant potential for the growth of the cement sector in India. While India continues to be the world’s second largest cement market, it has less than half the global average per capita cement consumption.

The tailwinds of rapid urbanisation, the growing middle class and affordable housing, together with the post-pandemic recovery in construction and other infrastructure sectors, are expected to continue driving the growth of the cement sector over the next several decades.

What are the Group’s plans for green cement production?

The Holcim deal is also in-line with Adani Group’s endeavour to embark on the path of greener cement production.

Cement manufacturing generates emissions resulting from chemical processes (60-70 per cent) and fossil fuel burning (30-40 per cent). Thus, it becomes imperative to explore opportunities for minimising emissions and optimising energy use.

The initiatives undertaken by the Indian cement sector so far to curb emissions have been restricted to operational advances such as energy efficiency, alternative fuel use, clinker substitution, etc. Unlocking further emission reduction potential calls for adoption of technological innovations aimed at greening the industry.

While the talk of ‘green cement’ in the Indian context is not new and the initial groundwork has already been laid out by a few cement giants, at present, there exists no comprehensive framework for certifying what makes cement a green product. Dalmia Cement had announced in 2018 its ambition of becoming carbon-negative by 2040 and has since then undertaken several measures, including augmenting the share of renewable energy used and so on.

Similarly, in 2021, ACC Limited launched ‘ECOPact’ (originally introduced by LafargeHolcim in 2020), a ready-to-use green concrete mix that involves 30-50 per cent lower embodied carbon content as compared to the conventional Ordinary Portland Cement.

Adani Group intends to leverage the technical know-how of Holcim and in-house renewable power generation to establish the cleanest and most sustainable cement manufacturing processes that will meet or exceed global benchmarks.

"Holcim's global leadership in cement production and sustainability best practices brings to us some of the cutting-edge technologies that will allow us to accelerate the path to greener cement production. In addition, Ambuja Cements and ACC are two of the strongest brands recognised across India. When augmented with our renewable power generation footprint, we gain a big headstart in the decarbonisation journey that is a must for cement production,” said Gautam Adani.

Introducing ElectionsHQ + 50 Ground Reports Project

The 2024 elections might seem easy to guess, but there are some important questions that shouldn't be missed.

Do freebies still sway voters? Do people prioritise infrastructure when voting? How will Punjab vote?

The answers to these questions provide great insights into where we, as a country, are headed in the years to come.

Swarajya is starting a project with an aim to do 50 solid ground stories and a smart commentary service on WhatsApp, a one-of-a-kind. We'd love your support during this election season.

Click below to contribute.

Latest