Science

World’s First 3D Printed Rocket Awaits Debut Flight After Two Scrubbed Launch Attempts

- An American aerospace company is all set to send its entirely 3D printed rocket — the world’s first — to orbit.

- Two of its launch attempts, on two different days, were scrubbed after issues were flagged last-minute.

- The company will hope third time's a charm.

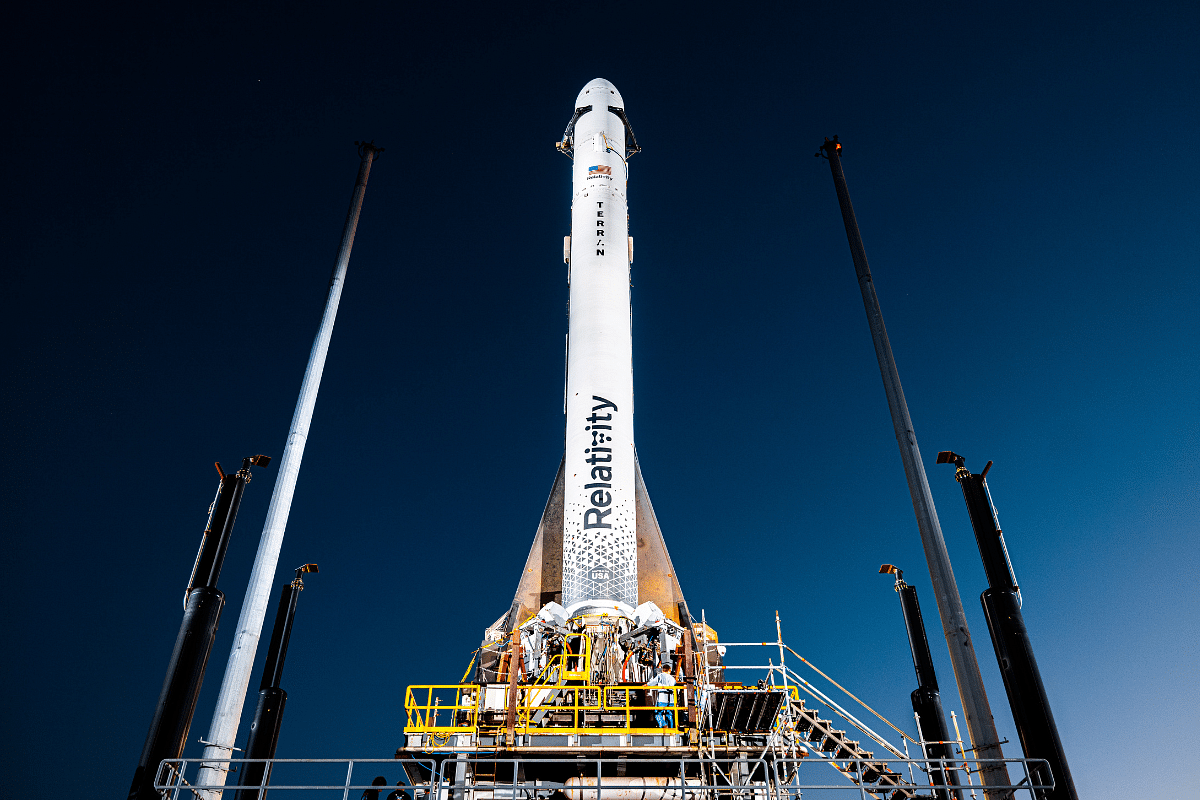

The Terran 1 rocket developed by American aerospace startup Relativity Space (Photo: Trevor Mahlmann)

American aerospace company Relativity Space is at the cusp of a landmark launch. Due to a couple of last-minute launch aborts over the last week, the stay at the cusp has been a prolonged one, though “good luck” and “fun” appear to be around the corner.

Relativity aims to send its entirely 3D printed rocket — the world’s first — called Terran 1 to orbit. The test mission, involving a prototype vehicle not carrying a customer payload, will mark the startup’s first orbital attempt with Terran 1, an innovatively made rocket that’s supposed to be less costly to make and fly.

The particular launcher that will shoot up from Launch Complex 16 in Cape Canaveral, Florida, is named “GLHF,” short for “Good Luck, Have Fun.”

Launch Attempts

The rocket was set for takeoff on 8 March 2023 within the 1pm to 4pm eastern time launch window (10.30pm to 1.30am, India time).

About 70 seconds before launch, the launch director called for a “hold” to address an issue. The stated cause of the abort was that the stage-two oxygen temperatures were “out of limits.”

A new launch time, with an extension of 45 minutes, was declared after a brief assessment.

Then, with about 23 minutes to go for launch, the attempt was called off for the day.

“Today’s launch attempt for #GLHF Terran 1 was scrubbed due to exceeding launch commit criteria limits for propellant thermal conditions on stage 2,” Relativity said in a tweet update.

The next launch window was days later because of the nature of the fuel used. “When using liquid natural gas, the methane needs time to get to the right concentration,” Relativity said.

A second launch attempt was scheduled for 11 March within the same 1pm to 4pm eastern time launch window (10.30pm to 1.30am, India time).

On the day, upper-level wind conditions posed a potential concern just hours before launch. It was still a go until the launch time was updated after a hold 20 minutes prior to launch.

Once again, a hold was called due to launch commit criteria violation. But after three new launch times were declared, the launch was finally scrubbed for the day.

(Relativity Space provided a “quick breakdown of the reasons for our aborts during terminal counts today” in a Twitter thread.)

The Rocket In Play

Terran 1 is a two-stage, expendable rocket, standing 110-foot (ft) tall and 7.5-ft wide. It is 85 per cent 3D printed by mass. (Relativity is working to lift that figure up to 95 per cent.)

The rocket can carry a maximum of 900 kilograms (kg) to sun synchronous orbit and a maximum of 1,250 kg to low-Earth orbit (LEO). A dedicated mission on the rocket would cost $12 million.

The launch vehicle is the largest 3D printed object to attempt orbital flight. Not only is the structure 3D printed, but so also are the engines. (Interestingly, anyone can print their very own GLHF Terran 1 at home, too.)

Remarkably, Relativity can turn raw material into Terran 1, and also Terran R, within just 60 days — integrating artificial intelligence (AI), robotics, and autonomous manufacturing technology.

The Terran rockets use 100 times fewer parts as compared to a traditional rocket, the company says.

Terran R is the world’s first fully reusable, entirely 3D printed rocket. It is a medium-to-heavy-payload reusable launch vehicle that will be capable of launching over 20,000 kg to LEO.

Terran 1 is a “pathfinder product” for Terran R.

Relativity uses Stargate, their metal 3D printer with AI-driven controls, to create its Terran rockets. Stargate is part of the company’s “Factory of the Future,” an aerospace platform to automate rocket manufacturing.

According to Relativity, they are “an application-layer 3D printing company that is starting with rockets, and will extend its Factory of the Future to all of aerospace.”

Terran 1 has nine 3D printed Aeon engines on its first stage and one Aeon Vac on its second stage.

The engines use liquid oxygen (LOX) and liquid natural gas (LNG), which, the startup believes, are not only the best-suited for rocket propulsion, but also for reusability. That’s not all — it’s the easiest to eventually make on Mars, too.

It’s the fuel of choice even for the Vulcan rocket of the prominent American space launch service provider United Launch Alliance.

Proving The Tech

It has been quite a journey for Relativity — the company started out as an idea on a Starbucks receipt and now faces the reality of a debut orbital launch that paves the way for grander space stuff.

This is still only the beginning for a company that aims to eventually build humanity’s industrial base on Mars. And it all starts with a successful launch.

With its debut flight, Relativity will be able to prove that 3D printing is a viable way to make rockets.

Thus, for Tim Ellis, the cofounder and chief executive of Relativity, going past Max-Q — the point in the launch sequence where the rocket experiences the maximum dynamic pressure — marks a major moment in the mission.

“…the key inflection in my mind is surpassing Max-Q, about 80 seconds into flight. We have already proven on the ground what we hope to prove in-flight – that when dynamic pressures and stresses on the vehicle are highest, 3D printed structures can withstand these forces. This will essentially prove the viability of using additive manufacturing tech to produce products that fly.”

Ultimately, though, “Our customers will really be our deciding jury,” Ellis says in a tweet, adding that the customers may be interested beyond the Max-Q point, to the later stages of the flight, like stage separation and second-stage engine ignition.

Ellis says their goal will be to provide their customers with confidence in their abilities, “especially with $1.65 billion in customer launch contracts already signed overwhelmingly for our larger reusable rocket Terran R, and billions more in our pipeline.”

“Medium-heavy lift is clearly where the biggest market opportunity is for the remaining decade, with a massive launch shortage in this payload class underway,” the Relativity chief wrote in a tweet.

Should Terran 1 pose “rocket science problems and not additive-related problems,” Ellis says they will consult with their customers to know whether to keep iterating on Terran 1 or instead “solve the remaining rocket science problems on the vehicle they are actually most interested in, Terran R.”

In any case, Terran 1 will supply useful data and insights, which will inform the design, development, and testing of Terran R. The latter is set for a debut launch from Cape Canaveral in 2024.

The Terran 1 launch will also be an early preview of software-defined aerospace manufacturing, which might be the way to go in the future.

As for getting Terran 1 off the ground, third time’s a charm, Relativity will hope. Good luck to them, with lots of fun, as well.

PS: Indian startup Agnikul Cosmos has developed and tested a single-piece, entirely 3D printed semi-cryogenic engine called Agnilet.

Introducing ElectionsHQ + 50 Ground Reports Project

The 2024 elections might seem easy to guess, but there are some important questions that shouldn't be missed.

Do freebies still sway voters? Do people prioritise infrastructure when voting? How will Punjab vote?

The answers to these questions provide great insights into where we, as a country, are headed in the years to come.

Swarajya is starting a project with an aim to do 50 solid ground stories and a smart commentary service on WhatsApp, a one-of-a-kind. We'd love your support during this election season.

Click below to contribute.

Latest