News Brief

India Plans To Produce Rare Earth Magnets Domestically In 3-4 Months Amid China's Weaponisation Of Supply Chain Dominance

Swarajya Staff

Jul 12, 2025, 02:07 PM | Updated 02:07 PM IST

Save & read from anywhere!

Bookmark stories for easy access on any device or the Swarajya app.

Union Minister for Coal and Mines G Kishan Reddy announced today (12 July) that India is accelerating efforts to manufacture permanent magnets domestically, following China's recent refusal to supply these critical components.

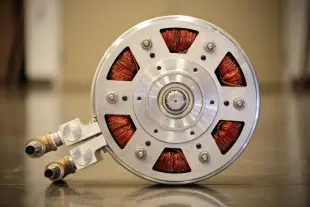

Permanent magnets, made from rare earth elements, are essential for technologies ranging from Electric Vehicles, turbines, space and defence applications.

Speaking to reporters in Hyderabad, Reddy highlighted the government's proactive steps to reduce India's 100 per cent dependency on China for these magnets.

"We used to be 100 per cent dependent on China for permanent magnets of the rare earths. But recently China has refused to supply," Reddy said.

He revealed that the mining ministry's institute in Hyderabad has developed a processing unit and equipment for permanent magnets, with plans to transfer the technology to private factories within three to four months.

"Our mining ministry's institute in Hyderabad has made efforts and prepared a permanent magnet processing unit with equipment. After three to four months, we will try to manufacture permanent magnets by giving the technology to different private factories," Reddy was quoted as saying by news agency ANI.

To incentivise domestic production, the government has introduced Production Linked Incentive (PLI) schemes.

Reddy emphasised the strategic importance of this initiative, noting Prime Minister Narendra Modi's ongoing discussions on the subject, including during his recent visits to five countries to explore international collaborations.

India faces challenges due to limited domestic production of rare earth raw materials, necessitating imports for processing.

"The raw material of rare earth is also available in less quantity in India. Importing that raw material, processing it, making permanent magnets for it, which is used from cell phones to space technology, including defence, there is a huge demand for this," the minister said.

The government is working seriously to address this, bringing the effort under broader schemes for critical minerals, the minister added.

This push comes amid global concerns over China's dominance in rare earth elements, which has raised fears of scarcity and price hikes.

China controls about 90 per cent of the global supply, posing risks to supply chains worldwide.

In April, China imposed tighter export controls on rare earth magnets — critical components for electric vehicles, wind turbines, and electronics.

The move resulted in a sharp drop in global shipments and rising uncertainty across supply chains.

Export approvals became slow and selective, forcing manufacturers across sectors to wait weeks for shipments or rework sourcing entirely.

India’s electric vehicle and auto parts industry was also among those hits by Chinese export curbs, with automakers reporting delays in sourcing magnets and electric motor component.

In response, a global counter-effort, including in India, is underway to diversify sourcing.

India is reportedly working on a plan to expand rare earth output.

The Modi government is reportedly planning to invest between Rs 3,500 crore and Rs 5,000 crore to provide incentives to companies to set up rare earth processing and magnet production facilities to meet local demand.

Further bolstering domestic priorities, state-run IREL (India) Limited was directed in June 2025 to suspend a 13-year-old export agreement with Japan, redirecting rare earth supplies for local use to reduce reliance on Chinese imports.

Also Read: '2026 Election Will Be Fought To Form A BJP-Led NDA Government': Amit Shah In Kerala