Business

How The Textile Sector PLI Aims To Solve A ‘Ready-Made Problem’

- To reduce dependency on cotton and to make RMG exports more broad-based, a PLI scheme was proposed in November 2020.

- The primary aim of this Production Linked Incentive (PLI) programme is to boost domestic manufacturing of man-made fibres, garments, and technical textiles.

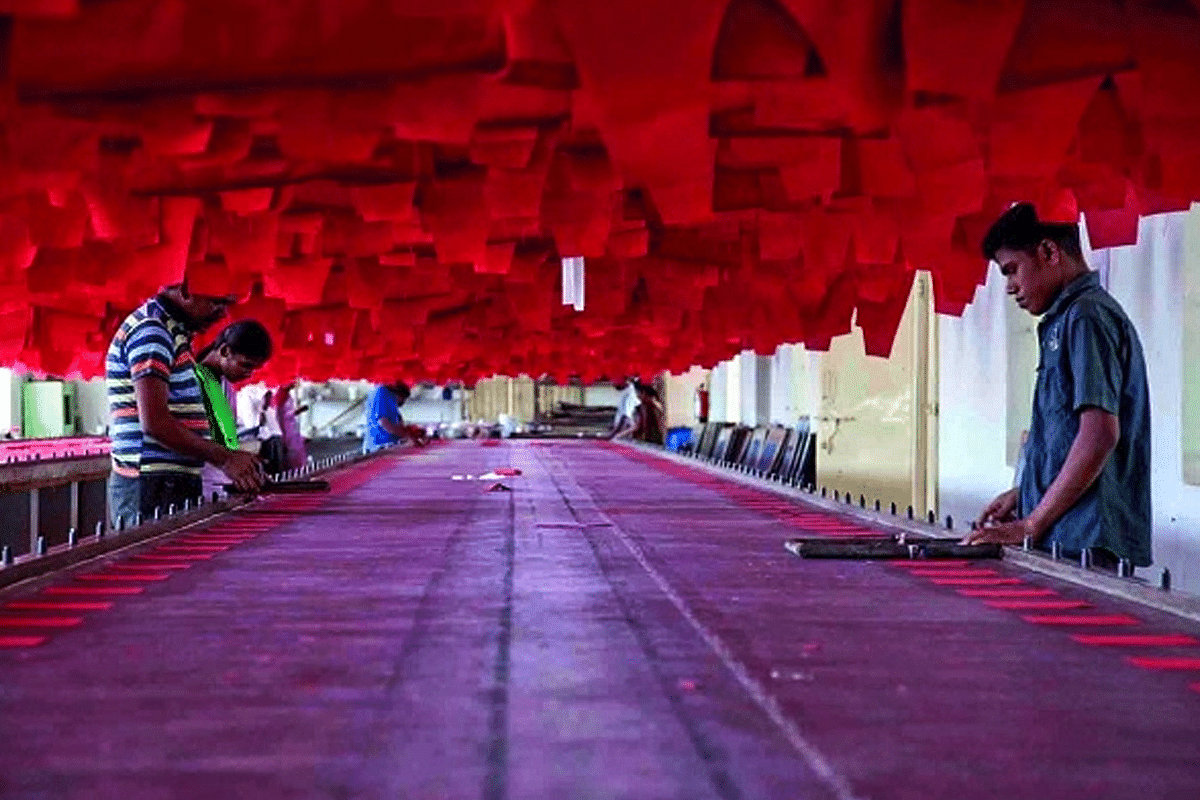

India textile factory workers (Wikimedia Commons)

Ready-made garments (RMG) exported from India include those made from cotton (including accessories), clothes made from man-made fibres (MMF), and from other textile material, wool, and silk.

Cotton (including accessories) contributes a lion’s share of this.

In fact, India is largely dependent on cotton (including accessories) for its RMG exports. The value of Indian MMF exports was roughly USD 2.6 billion in FY21, while world trade is about USD 200 billion. Meanwhile, MMF textiles account for 70 per cent of the total global consumption, followed by that of textiles made from natural fibres.

That’s why, RMG exports from India have remained stagnant, in the range of USD 16BN to USD 17.5BN during FY15 – FY19.

The world wants MMF, and India is mostly selling cotton.

To reduce this dependency on cotton and to make RMG exports more broad-based, a PLI scheme was proposed in November 2020 and the Union Cabinet recently approved it for a budgetary outlay of Rs 10,683 crore.

The primary aim of this Production Linked Incentive (PLI) programme is to boost domestic manufacturing of man-made fibres (MMF), garments, and technical textiles.

The main idea behind the scheme is to provide incentives over five years for manufacturing of these products. The estimation is that this scheme will attract fresh investment of more than Rs 19,000 crore, a cumulative turnover of over Rs 3 trillion, and create additional employment opportunities of more than 750,000 jobs in this sector.

Some of the highlights of this scheme are:

One, any person or company willing to invest a minimum of Rs 300 crore in a plant is eligible for the programme. Machinery, equipment, and civil works to produce MMF fabrics, garments, and products of Technical Textiles will be eligible for the first part of the scheme.

Two, investors willing to invest Rs 100 crore under the same conditions will be eligible for the second part of the scheme.

Three, the scheme focuses on Aspirational Districts, Tier 3, and Tier 4 towns.

Four, States that will likely be most benefited would be Gujarat, UP, Maharashtra, TN, Punjab, AP, Telangana, and Odisha.

Besides, the government also proposed a scheme of Mega Investment Textiles Parks (MITRA) in Union Budget 2021-22, to make India’s domestic textile industry globally competitive.

But what exactly are Man-Made Fibres?

Man-Made Fibres are made from various chemicals, or are regenerated from plant fibres. Examples would be Polyester, Polyamide – (nylon), Acrylics, Viscose (made from wood bark), Kevlar (a high-performance fibre), and Nomex (a high-performance fibre).

The technical application of MMF has increased with innovative developments. Fibre composites containing carbon fibre reinforced plastic have light weight features too.

The key benefits of MMF include:

One, they are strong — and can take up heavy things easily.

Two, Retain their original shape — Easy to wash and wear.

Three, they are elastic — can easily be stretched out

Four, softness.

Five, colour — varieties of colours available as they are manufactured.

Six, cost — Clothes made are generally cheaper than those made from natural fibres.

Seven, the filaments can be produced as fine or coarse as required, and staple lengths can be cut exactly to order.

Eight, wrinkle resistance, crease recovery, easy care properties.

Nine, light weight

Ten, high resistance to moth, mildew, insects, mould — simplifies storage

The domestic MMF industry in India comprises mainly of two components: Polyester and Viscose, which together account for about 94 per cent (in volume terms) of all MMF production in India.

Under this, polyester accounts for about 77.5 per cent, while Viscose accounts for the remaining share.

On a cumulative basis, MMF output declined by 27.6 per cent YoY to 2.4 Million Tonnes during April 2020 – January 2021.

The decrease was primarily due to an average decrease of 56.7 per cent in production during the first five months of FY21 because of Covid-19 disruptions.

Following this period, the production however increased.

India remained a net exporter of MMF during the period April 2020 – February 2021.

In absolute terms, the outbound shipments however declined by 17.5 per cent during this period, primarily due to Covid-19 disturbances.

The PLI scheme thus is a path-breaking initiative that GoI has undertaken to promote Indian textiles overall, with a justified focus on MMF and Technical Textiles.

The incentives will likely lead to greater investments in these textile categories, that form the bulk of global trade. It is also a way to usher in Atmanirbhar Bharat through focused investments in domestic textile manufacturing.

Support Swarajya's 50 Ground Reports Project & Sponsor A Story

Every general election Swarajya does a 50 ground reports project.

Aimed only at serious readers and those who appreciate the nuances of political undercurrents, the project provides a sense of India's electoral landscape. As you know, these reports are produced after considerable investment of travel, time and effort on the ground.

This time too we've kicked off the project in style and have covered over 30 constituencies already. If you're someone who appreciates such work and have enjoyed our coverage please consider sponsoring a ground report for just Rs 2999 to Rs 19,999 - it goes a long way in helping us produce more quality reportage.

You can also back this project by becoming a subscriber for as little as Rs 999 - so do click on this links and choose a plan that suits you and back us.

Click below to contribute.

Latest