Science

India Eases Research Rules: How GFR Reform Makes Life Easier For Scientists

Karan Kamble

Jun 20, 2025, 12:38 PM | Updated Jul 01, 2025, 09:17 AM IST

Save & read from anywhere!

Bookmark stories for easy access on any device or the Swarajya app.

In a corner of Professor Amitabha Bandyopadhyay's laboratory at the Indian Institute of Technology (IIT), Kanpur, sit three machines that tell the story of India's research procurement problem.

One, a 16-year-old German microtome, hums reliably as it has for nearly two decades, cutting tissue sections with the precision that made it the global standard.

Beside it stand two newer machines from Indian vendors — both silent, both broken, both representing Rs 15 lakh of taxpayer money altogether that might have been better used.

This isn't some tale of German engineering superiority. It's the story of how well-intentioned policies created a procurement maze that has frustrated researchers and slowed India's march towards scientific excellence…

Until now.

A recent government move is rewriting the script on research procurement. For India’s researchers, it’s a long-awaited relief.

The Procurement 'Punishment'

"The experience of buying anything in India is not that simple, right?" says Pravesh Biyani, a professor at the Indraprastha Institute of Information Technology (IIIT), Delhi, and founder of Chartr, a leading full-stack transit tech company dedicated to improving public transportation systems through technological solutions.

His observation would have most researchers across India nodding vigorously in agreement.

The challenge begins with tender specifications. "You have to float the right tender, because for every mistake that you commit in the tender, not exactly specifying what you want, you can get bids which are not what you want but are cheaper, and then you have to pick them," Biyani explains, painting a picture of public procurement for research and development (R&D) in India that strikes at the heart of scientific progress.

The constraint of buying made-in-India equipment — at least 50 per cent of it should have been made in India — beyond a certain level of spending not only narrows the supplier pool for procurement but also invites bids with wrongful made-in-India claims, leaving researchers with more headaches than they would like as they try to procure genuine research items that can potentially help them advance their research and ideally produce pathbreaking results.

"It is always a complicated and tiresome process to procure anything," Biyani says, calling it like it is. "The process at times becomes like a punishment."

His frustration begins with something as fundamental as specifying what he needs: "You just can't say that I want this DGX machine, which is Rs 50 lakh, let's say. I can't get that machine just by saying I want this machine. I have to procure this machine through various vendors. And we have to say that I want this specification, and then you hope that the specification will not be met by others but only by this machine. But, of course, then it could also lead to a single bid, which is a problem; you should also have multiple bids for the same thing."

In public procurement, the general advice is not to specify a brand but rather to specify the exact needs, commonly referred to as "technical specifications." Then, any supplier who can meet those specifications puts their hat in the ring. "It's fair to say that you don't want a brand; you want certain specifications to work for you. Please specify that, and then let whoever can bid come," Biyani acknowledges.

But just because it's fair doesn't mean the process isn't lengthy and cumbersome. Researchers are often left wishing for the process to be simpler and more straightforward, especially when time-sensitive research hangs in the balance.

When Time is the Enemy

For researchers, procurement delays aren't mere inconveniences — they can rob one of months or years of carefully planned work. The urgency becomes particularly acute in experimental sciences where timing is everything.

"I am a life scientist. What I can say is certain project objectives and certain project parameters are time-bound in my work," explains Prof Neelam Sangwan, who is Dean, Research, at the Central University of Haryana. Her field demands precision not just in execution but in timing.

She explains with an example that would resonate with experimental scientists across disciplines: "If I have to take an observation on a certain plant cell, a cancer cell, for a certain period of time and say if some chemical or consumable gets over during that time and I have to procure it urgently, or maybe some small equipment is urgently required, it has to be done right then because otherwise the experiment will be disturbed in the middle of its course, and then one has to repeat everything."

These time pressures are compounded by India's rigid financial year constraints. The digitisation of government accounts has made the 31 March deadline even more unforgiving.

"Earlier also it was like this, but now since most of the things are digitised, all the accounts are digitally operative. So 31st March means your amount is immediately adjusted and it becomes zero," Prof Sangwan explains. "So if we have not finished by then, it automatically won't be reflected in the further year financial grant."

This creates a peculiar pressure where researchers must race against fiscal calendars rather than scientific logic. The consequence extends beyond individual projects — agencies perceive researchers who cannot finish funds on time as inefficient, potentially reducing future allocations.

Prof Sangwan would like the overall procurement process to be more flexible to incorporate the unpredictable rhythms of research. "Getting more flexibility is desirable, especially for research, because people are experimenting. They are doing various experiments, and if they get stuck at any point, they have to start again from zero, involving more energy, material, research components, consumables, and also efforts," she says.

The inflexibility reaches absurd proportions in cases like that experienced by Digvijay Pratap Singh, who works as a research associate in the aerospace engineering department at the Indian Institute of Science (IISc). His experience illustrates how procurement rules create impossible situations for researchers working with cutting-edge technology.

"Let's say I am buying a thermal imager, which is costing around Rs 8, 9 lakh; above Rs 5 lakh, we have to have a mandatory local content certificate. IISc has its own rules, but the government rules are similar," Singh explains.

The challenge, he says, lies in India's manufacturing capabilities — or lack thereof.

In India, they don't really make any good sensors for the thermal imager. So Singh has to go in for one that's made outside India. But given the procurement rules — the sensor has to be procured abroad, and it will cost over Rs 5 lakh — he cannot directly buy it. "We have to go through a tender process. First, you apply for a domestic tender to see if there are any players in the market who can supply. If not, then you apply for a global tender. Global tender takes time — two, three, four months," Singh explains.

This is precious time lost. "If I am a PhD student working on a wing parameter and I want to study the pattern of how the wing deflects at various temperatures, I will need the sensor immediately. But I can't buy it immediately. For a global tender, it will take another three, four months. So this area is where we are facing most problems," Singh explains.

The government has provided an exemption list for global tender requirements; however, according to Singh, the 200-300 items that are on the list "are mostly medical equipment," leaving aerospace and other engineering disciplines largely uncovered.

Given this reality, some Indian researchers pursue various kinds of workarounds, such as combining the purchase of the desired equipment with that of an accessory item, just so that the overall extent of the local content goes up — a bureaucratic dance that wastes time and energy that could be spent on actual research.

The Microtome Trap

Perhaps no single example better illustrates the problem created by India's procurement rules than Prof Bandyopadhyay's experience with laboratory microtomes, shared in a social media post.

His saga began with what should have been a routine Rs 15 lakh equipment purchase for importing a precision instrument for cutting tissue sections. Instead, it became a masterclass in how procurement rules designed to support domestic industry can trap researchers in hard choices.

Typically, the process unfolds with a wait all too familiar to Indian research: the institute collects import requests biannually before sending them to the ministry for global tender approval. Nine months minimum just to place an order, consuming a quarter of most research grant periods before any actual work could begin. Then another six months for installation, assuming everything goes smoothly — which it rarely does.

But the real complexity emerged from the Government e-Marketplace (GeM) and Government Trade Portal (GTE) requirements mandating that researchers demonstrate no Indian alternative exists before importing equipment. For microtomes — precision instruments used worldwide — this created an opening that some Indian vendors were quick to exploit.

"Worldwide researchers use a machine from a specific German company for generating very thin tissue sections," Prof Bandyopadhyay explains. "Because of this rule, some Indian vendors started selling the same equipment. They will simply photocopy the specs of the German company and sell their product through GeM at 50% price of the German company."

The choice became stark: buy the Indian alternative or face indefinite delays in import approval. Prof Bandyopadhyay chose pragmatically, going ahead with made-in-India machines that matched the technical specifications he sought — and suffered predictably.

"Now, you have no option but to buy from them. The machine won't even work for one year." When he contacted vendors about warranty service, they would "flatly refuse to offer warranty service."

The contrast with his equipment purchased tells the entire story: "I have three such machines — one from the German company before these rules came in (16 years and still working) and 2 from Indian vendors (less than five years old and not working)."

The human cost of this system became clear when his students desperately needed a second functional machine. "I had the money but could not provide for them," he says, capturing the frustration of research leaders unable to provide essential tools despite having allocated funds. "Thus, tax payers money were being wasted after fraud companies and students were suffering (sic)."

This was a case of well-intentioned policies but where compliance with domestic sourcing requirements became more important than equipment functionality, ultimately harming both research quality and public finances.

A Bureaucratic Awakening

However, researchers found a reason to rejoice recently.

By 2025, the accumulated frustration from the research community had reached policymakers' ears. Recognising the longstanding pain of procurement, which has had the undesirable effect of slowing R&D in India, the Government of India took decisive action.

On 5 June 2025, a notification that would prove quietly far-reaching amended the General Financial Rules (GFR) of 2017 to enhance the ease of doing research in the country.

The changes relaxed procurement rules specifically for scientific and research organisations, making it easier and faster for them to buy equipment and supplies needed for research.

Perhaps most notably, beyond its specific benefits, the notification represented a clear and open acknowledgement of the fact that scientific research has unique procurement needs that deserve special, faster procedures — a recognition that had been long overdue in India's research ecosystem.

The Significance of GFR Relaxation for Research

The unassuming circular quietly unlocked a whole range of benefits for India's research community, from less red tape to faster access to tools, from easier global sourcing to autonomy for the leaders of research institutions.

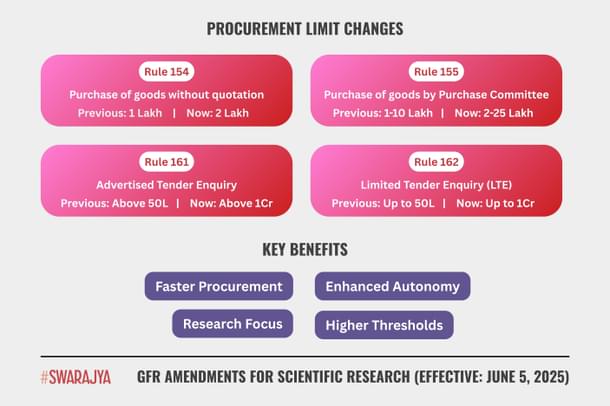

Higher spending limits without complex procedures: Previously, purchases above Rs 1 lakh required quotations or tenders. Now researchers can buy up to Rs 2 lakh directly without quotations. For the purchase of goods by the purchase committee, the limit has been increased from Rs 10 lakh to Rs 25 lakh — a 150 per cent increase that eliminates bureaucratic hurdles for mid-range equipment purchases.

Faster procurement for expensive equipment: The limit for "limited tender enquiry" (LTE) has been raised from Rs 50 lakh to Rs 1 crore, while that for "advertised tender enquiry" (ATE) has been raised to purchases exceeding Rs 1 crore.

LTE is a restricted procurement method where invitations are sent only to a pre-selected list of suppliers or contractors. The procurement process is generally fast because fewer bidders are involved, while remaining within the realm of competitive bidding. It also proves cost-effective for routine or low-value purchases.

ATE, on the other hand, is an open procurement method with public advertisement. A notice gets published in newspapers, government websites, and tender portals. Any eligible supplier meeting the qualification criteria can participate, ensuring maximum competition and transparency. The process requires more time, but the wider market reach potentially leads to better prices and innovation.

By increasing the LTE and ATE tender limits, the government has potentially cut down bureaucratic delays for buying costly research instruments — exactly the kind of equipment that researchers like Singh and Bandyopadhyay have struggled to procure efficiently.

Online marketplace flexibility: Research institutions have been given the green light to use non-government e-marketplaces (non-GeM), like Amazon or Flipkart, to buy stuff they need. This gives researchers access to a wider variety of scientific equipment and faster delivery options.

GeM is a dedicated online marketplace for the buying and selling of goods and services by the government, including its various departments and public sector undertakings (PSUs). It was introduced in 2017 to enhance transparency, efficiency, and speed in public procurement.

Though it has been convenient and useful for many government purchases, GeM doesn't always have everything a researcher may need. With the new rule allowing procurement of scientific equipment and consumables outside of GeM, researchers will now have a wider supplier pool from which to buy the materials necessary to advance their research projects.

Global sourcing approved: Researchers can now import high-end equipment via global tenders up to Rs 200 crore if justified, with vice chancellors and directors put in charge of the issuance of global tender enquiry (GTE), removing a significant bottleneck in the import process.

Autonomy for vice chancellors and directors: Under certain conditions, trusted leaders in research institutions can take independent decisions to accelerate innovation, reducing the need for distant bureaucratic approvals that often slow down time-sensitive research projects.

Who benefits: The reforms apply to the Departments of Science and Technology (DST), Biotechnology, Scientific and Industrial Research, Atomic Energy, Space, and Health Research (including the Indian Council of Medical Research); the Ministry of Earth Sciences; the Defence Research and Development Organisation (DRDO); the Indian Council of Agricultural Research (ICAR), including its affiliated institutions and universities; and universities and institutes doing doctoral or research work.

Researchers Rejoice — With Measured Optimism

The response from India's research community was swift and overwhelmingly positive, though tempered with awareness of remaining challenges.

"I have written and spoken often about the 5Gs plaguing India's research ecosystem. Glad to see that three of them — GFR, GeM, and GTE — have now been addressed," V Ramgopal Rao, the Group Vice-Chancellor for the Birla Institute of Technology & Science (BITS) Pilani, said in a social media post, adding, "This will go a long way in improving the ease of doing research in the country."

Prof Bandyopadhyay similarly noted, "Many of us have raised the issues related to purchases for R&D purposes while following GFR17 norms. A modified norm has now been notified which addresses most of the issues related to such procurements."

Just as Rao thanked DST Secretary Abhay Karandikar "for his relentless efforts," Prof Biyani said, "I think DST Secretary Karandikar and others have done a great job. Because they were researchers for a long, long time, they understood us, and they kind of told the government that, look, this is coming in the way and a lot of time is being spent on some of these things."

For Prof Biyani, this relaxation in research procurement norms represents something deeper than procedural reform. It signals increased government trust in researchers.

"It is good to see that the limits have increased. It is good to see that for lower limits, we don't require that many processes. So the trust of the government in its researchers seems to have increased. They don't think that we are here to cheat anybody, which we are not — at least most of us are not, I am sure. And those who would be wanting to mislead or misappropriate would anyway do it through tenders also. I think, in a way, it is good that there is an increased level of trust," he tells this writer.

"This is what we were seeking," Prof Sangwan says emphatically. She believes this move will reduce the time taken and cut down the delays that were earlier par for the course while making purchases for research purposes.

"This is a great relief for researchers because sometimes we end up in a situation where, say, you borrow a certain chemical from others, but for how long will you borrow it? Sometimes, the other person also has only a limited amount," she says. Easing the procurement process addresses some of these fundamental challenges that have long plagued Indian research.

Individuals who are new to research, such as newly appointed principal investigators (PIs) in research projects, stand to benefit especially from the relaxed rules.

"For the new research PIs who have started research for the first time in their labs, they don't have much of these stocks (like chemicals) piled up with them. For them, the continuous supply of chemicals, consumables, and, of course, the procurement of equipment will help speed up their progress," Prof Sangwan explains.

Equally important is the benefit for startups at a time when India is undergoing a major shift from purely academic pursuits to translational research in the country.

"Say someone is putting up a startup. If that person is delayed for weeks or a month or more, it becomes very tough on them. Because something is held up, the next step cannot come," Prof Sangwan says.

The latest move, therefore, is like a "gift" for researchers, especially for those involved in translational research, according to Prof Sangwan. "Now we are shifting from just a fundamental mode to the innovator style the way other developed countries are progressing. So we are also now looking into how our research can enter into the translational mode. I think this release will be very useful to all of us because this is an add-on gift or facilitation which comes our way as a scientist or a researcher or a faculty member," she says.

Just a Partial Rollback?

While the latest relaxation of norms for R&D procurement is universally welcomed by the research community, some have pointed out that what's being celebrated is not a new move to advance R&D in India but a partial rollback of the very same rules that were previously holding research procurement back and which were, in fact, baked into the GFR 2017 rules.

"Why was GeM introduced in the first place?" wondered some within the research community, highlighting the cyclical nature of policy reform.

It was the Ministry of Finance that made it mandatory for government users to make purchases through GeM by adding Rule 149 to the GFR, 2017 — a rule that researchers now celebrate being exempted from.

"When the process has a problem, exemption is not the solution. Improving the process is," Udaya Kumar, Scientist-G and Director, Geospatial Technology and Services Division, National Informatics Centre, noted in a social media post, pointing to the need for more fundamental reforms rather than sector-specific exemptions.

Curiously, in Singh's experience, IISc has already been following these relaxed procurement limits before the release of the circular. "This order has come very late because this practice has been going on since 2020, since Covid came. This limit has been increased to Rs 2.5 lakh and Rs 25 lakh. I don't know why they released this order so late," the aerospace engineer claimed, suggesting that practical necessity had already driven informal adoption of these more flexible approaches.

Room for Improvement: The Quality Conundrum

Singh suggests there is much more that needs to be done to ease procurement for research purposes, primarily concerning the push for 'Make in India' in procurement.

"How many companies are there in India that make computer desktop cabinets? We don't have them. Good SMPS — the power supply which goes into computer systems? We don't even have that. If you don't have these local things in good quality, then why are you barring us from buying from foreign countries? You are saying don't buy from China. Yes. But if we don't have lithium in our country, how do we buy batteries? If we have to buy batteries, we have to buy from China," Singh says, highlighting the fundamental contradictions in current policy.

He recounts an experience he had at IIT Madras which shows how impediments to procurement hamper R&D productivity.

"At IIT Madras, they needed a stress test testing machine. And there's a market for it in India, but the controller part is not good. It's not Indian-made. So they had to buy it from Germany. Now they have a testing machine. Their controller is gone. It's not working. They need to buy the controller. For the controller, because it's costing more than Rs 25 lakh, they need to wait at least three to four months (with the existing global tender process). For that time period, that machine is completely useless," Singh explains.

The research associate suggests that perhaps the government could look at cases on an individual basis. "Let's say I need the item immediately. And my professor, or chairman, or the designated authority has signed off on it, saying we need this immediately; then you need to give us this bypass for the tender and other steps in the process."

With the Make-in-India push, there is also the problem of Indian companies making cheaper, lower-quality equipment and winning bids, thereby leaving researchers with faulty equipment, like what happened to Prof Bandyopadhyay.

"At Aerospace Engineering in IISc, there is a basic lathe machine which came from the US, Massachusetts, in 1917. It's been more than 100 years, and that machine is still functioning; people work on that. Whereas we have bought many machines from the local market that have not lasted at all. What's the point of buying a machine when most of the days it is in repair?" Singh says.

Prof Sangwan agrees this is a major pain point. "In India, many equipment of comparable quality are yet to come. That is definitely an issue. The Indian vendors sometimes will offer something which will definitely be L1 (lowest bidder). But that quality standard may be a point of concern," she says.

However, the life scientist sees here a huge potential for India.

"This area — manufacturing, 'Make in India' — is where we have huge scope. Western countries are manufacturing high-end equipment, and we are buying them. There's a lot of revenue which is going to them. And the reason is, again, definitely, the quality. Some Indian companies have tried to compete and have improved their products, but there is a long way to go before these could become a preferred choice. Of course, the very standard and good vendors from abroad, they have invented or manufactured their equipment, and they are running it better. But that is why I say this is the area where India can make major strides in the future and turn 'Make in India' into reality," Prof Sangwan says.

According to Prof Bandyopadhyay, the problem lies not in the make-in-India clauses but in the quality control of what's made in India. "I firmly believe that both GeM and made-in-India clauses will be immensely beneficial for the Indian R&D ecosystem," he says.

A couple of reforms, however, would make a tremendous difference. "Only OEMs (original equipment manufacturers) should be allowed to register on GeM for the purpose of selling equipment or machines," he says, and strict quality and standards control — through third-party validation — should be ensured.

"Imagine that the two microtomes that I procured were of as good quality as the German microtome. Then I would have got my research procurement at 50 per cent the cost. And that would allow me to do more with my grant money. Therefore, 'Made in India' is a very good push. But it cannot be just the stricture that you have to procure 'Made in India'; it has to be also the stricture of the manufacturers that they have to demonstrate quality through third-party evaluation, and that's where testing and standards are so important," the IIT Kanpur professor says.

"If somebody was to come up to me and say that I have a product and I want to validate it, verify it, my first reaction would be, 'Let us look at the availability of a standard,'" says Anil Jauhri, who has over four decades of experience in the field of quality, standards, certification, accreditation, and technical regulations, having served as the chief executive officer (CEO) of the National Accreditation Board for Certification Bodies (NABCB) and worked at the national standards body, Bureau of Indian Standards (BIS).

"The easiest would be to look at BIS standards; whether out of those 25,000 standards they have made, there is a standard which is corresponding to this product. If there is one, then half my problem is solved. There is a reference point against which I have to test it or verify it," he says.

But here a challenge might emerge. If the extent of the particular product's manufacturing in India is minimal or absent, testing facilities will be hard to come by. This is because there wouldn't have been the need to set up testing facilities for that product.

"Sometimes, in such a situation, I would talk to IITs or engineering colleges and ask if somebody has a facility because in the teaching domain, if there are facilities which can be used for this purpose, fine; commercially, a lab would not be available. Because there is no manufacturing, no demand for testing, and therefore, there will be no commercial labs, certainly." One option would be to look at testing facilities overseas.

In case there are no corresponding BIS standards, one could look at international standards like the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) with its speciality in electrical equipment.

"In today's world, it's likely that for anything you make, there is a standard somewhere. And given the kind of tools we have today — Google search, AI (artificial intelligence), etc — it should be possible to identify if there is a standard somewhere for this product or this machine. This is how I would go about it," Jauhri says.

Acknowledging the made-in-India quality problem, Prof Biyani believes researchers can do more at the outset to prevent bids from low-quality, domestic manufacturers.

"Quality is the biggest issue. And I don't think GeM or anybody can solve it that well. It is a complicated problem. The purpose of opening it up for everybody to bid is to be fair to everybody. Otherwise the big players will just eat up everything, and there will be no innovation, and these guys will then raise the prices. Thanks to the cronyism of big folks, this has to be done. So researchers will have to find a way to ensure that the bids are written in a way that the poor-quality stuff, for example, does not get passed through the stages," the Chartr founder explains.

He expects researchers to do some of the heavy-lifting. "Some diligence has to be done from the researcher's side as well, which unfortunately takes their time, which it should not, but there is nothing that can be done because it's public money. I think it's a responsibility to be careful with it. And if it requires some extra time, so be it. I think it's a complicated problem. Government is trying their best, but I don't think government can solve it fully. It has to be a collaborative effort," Prof Biyani says.

He assures that existing mechanisms, including GeM, allow researchers to verify the quality of suppliers better. "I know that if you report something to GeM, they take very strong actions against those who are faking the quality. For example, they can be debarred," he says.

Beyond Procurement: The Broader Reform Agenda

The recent GFR amendments are significant. However, several structural issues continue to constrain researchers even beyond procurement bottlenecks.

The rigid caps on contingency charges create artificial constraints on research flexibility. Many Department of Science and Technology projects, for instance, limit contingency expenses to less than 3 per cent of total recurring costs, while institutional overheads are capped at a maximum of 10 per cent for central and state government institutions or Rs 100,000 per year. These limitations often force researchers into creative accounting rather than focusing on actual research outcomes.

The fundamental approach to equipment procurement also needs rethinking. The current L1 (lowest bidder) system, while fair in principle, often prioritises cost over quality and long-term utility. For specialised scientific equipment, a shift towards a best-value approach would serve research interests better.

Such an evaluation framework would assess bids based on comprehensive criteria including quality, technical suitability, long-term utility, and maintenance requirements rather than just upfront costs.

International best practices offer valuable lessons here. The European Union's value-based tendering model in medical technology procurement, for example, evaluates suppliers on innovation potential, lifecycle costs, and clinical outcomes rather than just initial pricing. Adapting such approaches for scientific equipment could help avoid the kind of quality disasters that plagued Prof Bandyopadhyay's laboratory.

The time has come to consider developing differentiated procurement frameworks specifically tailored for research needs. Rather than applying general administrative purchase rules to specialised scientific equipment, tiered procurement rules could recognise that research has fundamentally different requirements from routine government purchases.

Such specialised GFRs would acknowledge that scientific equipment often requires technical expertise to evaluate, has longer useful lives, and serves purposes that standard bureaucratic procurement frameworks weren't designed to handle.

Furthermore, the policy requiring the return of unspent funds or remittance of earned interest needs serious reconsideration. In the current system, researchers feel pressured to spend allocated funds by arbitrary deadlines rather than when scientific logic demands it. Allowing institutions to retain a certain percentage of unspent funds for future research or to reinvest interest earned into research infrastructure would align financial incentives with scientific objectives rather than fiscal year calendars.

As for what else could follow the relaxation in procurement norms to further improve ease of doing research in India, Prof Biyani recommends monitoring the latest change, seeing what comes of it, and then making improvements based on the results.

"What we don't do is we don't start with the definition of success and then see what happened — if we overachieved or underachieved, what did we estimate wrong, what did we estimate right — and then change the course. So more than changes, monitoring the changes and understanding what has happened post the change is more important," he explains.

A More Fundamental Rethink?

Some policy experts argue that truly transforming India's research ecosystem requires more radical changes than even the progressive GFR amendments represent.

In their 2024 paper, titled Rethinking innovation policy in India: Amplifying spillovers through contracting-out, R A Mashelkar, the former director general of the Council of Scientific and Industrial Research (CSIR), along with Ajay Shah and Susan Thomas of the non-profit research organisation XKDR, proposed revisions to the GFR but within a certain context — "a reorientation of public spending on innovation: away from building vertical government organisations, and in favour of a contracting-out strategy."

They made the case for a switch from the predominantly 'make' approach followed by India to a predominantly 'buy' approach, such as can be seen in the cases of the United States's premier agencies, the National Aeronautics and Space Administration (NASA) and the National Institute of Health (NIH). Part of the path to implementing this 'rethink' is a revision to GFR, according to the authors.

Broadly, Mashelkar et al proposed that scientists, not officials, be in charge of monitoring scientific projects; bidding and tendering requirements be removed for research-related procurement; the issuance of grants to private, for-profit firms be extended; the use of cost-plus contracts be incentivised, allowing for "good faith efforts" and not "delivery" of the goods or services to be the test for discharge from the contract; and the introduction of a chapter on the process of peer review be the method of evaluating research.

Distilling the essence of his paper to this writer, Shah explains the fundamental incompatibility between current procurement thinking and research reality:

"At present, government contracting is oriented towards buying pencils. If you fail to deliver pencils, we will not pay you, or we will sue you. That's fundamentally incompatible with risk-taking. If it's not risk-taking, it's not research."

His observation crystallises a deeper philosophical truth about research and failure: "A sophisticated society is one in which failure takes place without blame."

Looking Forward

The June 2025 GFR amendments represent significant progress in recognising research's unique needs. Yet there is still a way to go. It will take not just procedural reforms but a fundamental shift in how the country balances transparency, domestic industry support, and scientific innovation to significantly advance India's research work.

As Biyani suggests, the real test lies in monitoring these changes, understanding their impact, and continuing to evolve based on results.

For now, researchers across India are optimistic. Whether this bureaucratic breakthrough translates into scientific breakthroughs remains to be seen. But certainly India's researchers have reason to believe that their biggest obstacles might not be procedural after all.

In Prof Bandyopadhyay's lab, that 16-year-old German microtome continues its reliable work, no longer a solitary reminder of what Indian research could be. Instead, it may soon have proper company — functioning equipment purchased through systems designed to enable discovery rather than discourage it.

Karan Kamble writes on science and technology. He occasionally wears the hat of a video anchor for Swarajya's online video programmes.