Science

Indian Success Story: A Bengaluru Lab Is Churning Out High-Quality Mirrors For Giant Next-Generation Telescope

Karan Kamble

May 09, 2024, 01:09 PM | Updated 01:18 PM IST

Save & read from anywhere!

Bookmark stories for easy access on any device or the Swarajya app.

India marked a milestone recently with its work on an international mega-science project to build a highly advanced observatory at Mauna Kea, the highest peak on the island of Hawai'i and the second-highest for any island on Earth.

Collaborating to build the Thirty Metre Telescope (TMT), India is helping create a significant share of the building blocks — the mirror segments — that will make up the 30-metre (m) primary mirror.

The largest of its kind, the giant mirror will pick up on optical, near-infrared, and mid-infrared light coming in from the cosmos. Scientists will study the incoming data and expand our understanding of the universe.

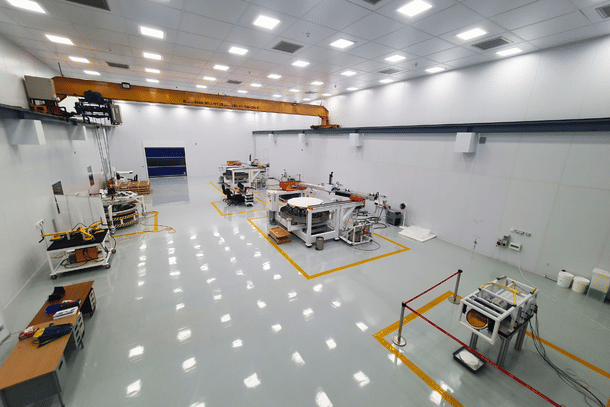

India’s share of the work on the mirror segments is underway at a specialised facility called the India-TMT Optics Fabrication Facility (ITOFF), located about 40 kilometres (km) from Bengaluru, Karnataka.

The facility resides within the Centre for Research and Education in Science and Technology (CREST), a campus of the Koramangala-based Indian Institute of Astrophysics (IIA).

ITOFF is the first-of-its-kind mirror segment fabrication facility for large telescopes in India. It was designed and built for the manufacturing of the TMT primary mirror segments and inaugurated on 29 December 2020.

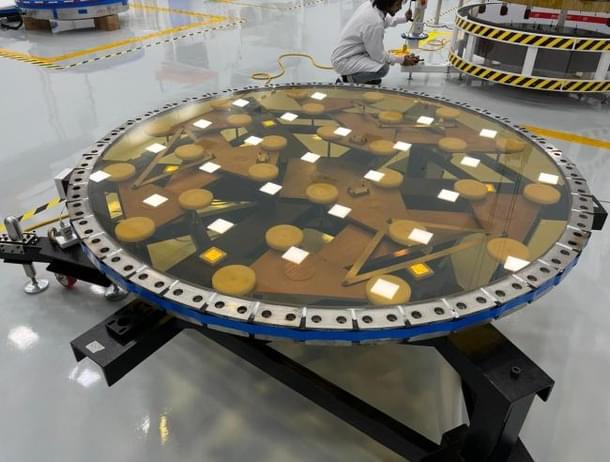

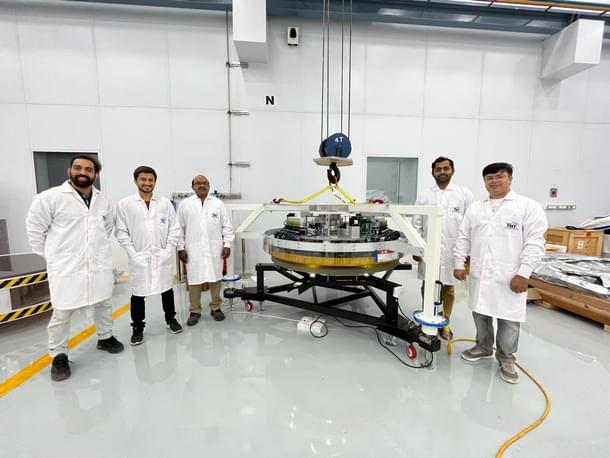

In a milestone, the first mirror roundel for the telescope was successfully polished recently at ITOFF, which happens to be the only facility in India for polishing thin, aspherical, off-axis, non-axial symmetric mirror segments.

A roundel is a circular segment 1.52 m in diameter, 45 mm thick, and weighing 0.25 metric tonnes. It is precisely cut and polished to an accuracy of less than 2 microns (micrometres).

Thereafter, it is machined into a hexagonal mirror segment that will one day join more than 490 others to form the telescope’s main mirror.

ITOFF engineers say the facility is transforming TMT mirror blanks into high-quality surface hexagonal mirror segments using the stress mirror polishing (SMP) technology.

Eighteen mirror blanks from Japan’s premiere optical glass manufacturer OHARA Inc and National Astronomical Observatory of Japan are now at the facility for polishing. They will soon undergo a mechanical grinding treatment and be polished accurately into a smooth aspherical shape.

Besides fabrication, metrology is a key aspect concerning the roundel. Engineers are using a two-dimensional (2D) profilometer to measure the curvature and warping of the mirror roundels.

The profilometer has 61 probes that measure each roundel six times. “That’s a whopping 366 data points per mirror roundel!” says IIA Bengaluru in a short video.

The latest accomplishment is an “important milestone towards the production of the mirror segments for the Thirty Meter Telescope @TMTHawaii!” IIA Bengaluru said on X.

“This is one of the kinds of technologies only a couple of countries (USA and Japan) have. The facility (ITOFF) will meet the needs of future large segmented apertures for both space- and ground-based telescopes. This is one of the key success stories of India's participation in the TMT project — a global endeavour,” Professor B Eswar Reddy, Programme Director, India-TMT, said.

“Generating an off-axis, non-axial symmetric aspherical shape over a thin, large optical blank is highly challenging with the conventional method of glass polishing, and it would take years together to achieve the required shape over single glass with high-end computer controlled machines. The technology used for polishing TMT glass roundels, called stress mirror polishing (otherwise called the bend and polish technique), would yield a polished roundel in two weeks. Thanks to Jerry Nelson, USA, the inventor of SMP technology for large optics fabrication,” S Sriram, Work Package Manager, Optics Fabrication Lead Engineer, India-TMT, said.

“Congratulations on a great beginning!” Professor G C Anupama, an astronomer at IIA and a core member of India-TMT, said on X.

The TMT promises to revolutionise our understanding of the universe and our place within it. Scientists will use it to explore black holes, dark matter, and the possibility of life outside the solar system, among other things.

In the process, they will seek to answer such scientific questions as what is the nature and composition of the universe, when did the first galaxies form and how did they evolve, how do stars and planets form, and is there life elsewhere in the universe.

Fortunately, the TMT is designed to be capable of answering these hard questions — it features the latest innovations in precision control, segmented mirror design, and adaptive optics.

Strikingly, it will have more light gathering power than the 10 largest ground-based telescopes in existence combined, and its images will be more than four times sharper than that of the mighty James Webb Space Telescope.

The telescope’s core component is the 30-m mirror, which will be composed of 492 individual 1.4-m hexagonal segments aligned to form a single reflective surface. After it is ready, the primary mirror will be the largest in the Northern Hemisphere.

The individual TMT mirror segments are being made by three organisations — Coherent in California, the United States (US); Canon in Japan; and IIA Bengaluru, India.

India will supply 84 of the 492 mirror segments and 82 spare units, or nearly 15 per cent of the total number, all of them processed at ITOFF. The country’s other contributions will include segment support assemblies, software, electronics, sensors, actuators, and science instruments.

As a 10 per cent partner, Indian astronomers are likely to get about 36 nights of TMT telescope time in a year — that’s a precious length of time, as time on any telescope, let alone on one of the world’s largest ground telescopes, is in very short supply worldwide.

The TMT is being built jointly by the California Institute of Technology and the University of California in the US, the National Institutes of Natural Sciences of Japan, the National Research Council of Canada, and the Department of Science and Technology (DST) of India.

India became a full partner in the TMT project in December 2014. The India-TMT effort is being led by IIA Bengaluru, the Aryabhatta Research Institute for Observational Sciences (ARIES), Nainital, and the Inter-University Centre for Astronomy and Astrophysics (IUCAA), Pune. IIA Bengaluru serves as the nodal agency for the India TMT Coordination Centre (ITCC).

The Indian share of the project is being funded by DST and the Department of Atomic Energy.

Karan Kamble writes on science and technology. He occasionally wears the hat of a video anchor for Swarajya's online video programmes.