Tech

Reality Check: Will India Become A Global Semiconductor Hub Soon?

Arun Mampazhy

Oct 09, 2022, 12:13 PM | Updated 12:23 PM IST

Save & read from anywhere!

Bookmark stories for easy access on any device or the Swarajya app.

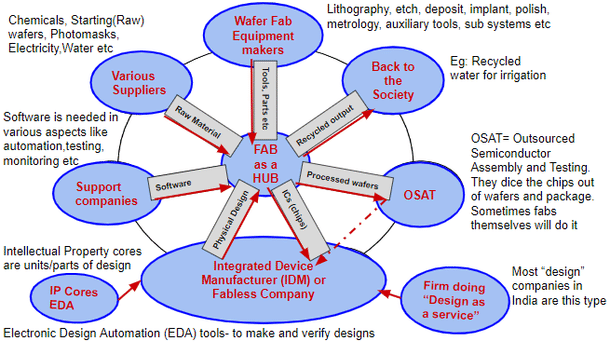

A few weeks ago, I was pointed to an interesting picture (shared below) showing the semiconductor ecosystem or supply chain.

For the uninitiated, “fabless” like Qualcomm and MediaTek design and sell chips, but do not fabricate them.

“Foundries” like Taiwan Semiconductor Manufacturing Company (TSMC) and GlobalFoundries do not “own” chips, but fabricate them on a contract basis.

“Integrated Device Manufacturers” (IDM) design and fabricate chips.

Micron, for example, uses its fabrication facilities (fabs) for its own chips, while Samsung uses them for both internal and external orders. Intel is in the process of catering to external orders in addition to its internal ones.

The picture got me thinking on a few counts.

First, out of all the top players listed, there is not a single Indian company. In fact, no such firm of global significance exists in any sub-category.

The presence of “support” or “R&D” (research and development) centres does not make India a “semiconductor design power house,” as some often exaggerate.

Such claims can be true only if the design industry (fabless or IDM), headquartered in India and which “owns” chips, is qualitatively and quantitatively big.

Second, when someone writes “India will soon become a semiconductor hub,” I can understand the sentiment as well as the hope and wish behind it. But it is important to step back and reflect on the real meaning of those words and whether the claim is factually correct.

As part of India’s semiconductor incentive scheme, the three silicon fab proposals that are in “review” since February this year will together have a maximum of 120,000 wafers-per-month capacity of 65-28nm process nodes when fully operational; that is, in about seven to eight years if all goes well.

Using available wafer price information, in the best-case scenario, these three fabs may generate an annual revenue of about $3.6 billion by 2030. Indications are that foundry revenue globally will be about $180 billion or more by 2030 and so, India’s share is likely to be 2 per cent or less.

It will still be a big achievement for a country that neglected this field for 50 years, but it won’t make India a “hub.”

Third, on whether that 1 or 2 per cent supply will cater to domestic needs or exports — let business decide what works best.

Filling fabs and getting to profitability should be the primary goal. The government and its proxies should hold back on their obsession with words like “domestic” or “consumption.”

In the absence of fabless Indian companies that can give high-volume orders to fabs in India, chip “ownership” will mostly remain outside India. But in no way should that be an excuse to slow down decisions on fabs.

Getting caught up in such nuances goes against the spirit of Prime Minister Narendra Modi’s words that “Government has no business to be in business.” Moreover, it gives the impression of trying to write the birth chart of a baby not yet born.

The overall semiconductor revenue, which includes fabless and IDM, was nearly $600 billion in 2021 and is likely to cross $800 billion by 2030. Like what happened in Taiwan, if the presence of fabs facilitates some fabless companies with revenues of $1 billion or more, it may get India a 1 or 2 per cent share in overall semiconductor revenue as well.

Only time will prove the efficacy of schemes such as the design-linked incentives as part of India’s semiconductor push. India, in general, and semiconductor design enthusiasts, in particular, will need a big change in mindset — from service to product development, that too of global standards and not just with a view to cater to “local” needs.

“Make in India, for the World” should not be limited just to running a branch of a multinational corporation on Indian soil; “Brand India Global Reach” (BIGR) must be the guiding mantra.

Finally, are foundries indeed at the “top of the pyramid?”

That is one way of looking at it. For whatever it’s worth, I attempted a different picture with fab (owned either by a pure-play foundry or an IDM) as the “hub” along with “spokes” (peripheral players).

The next time someone says “India will be a semiconductor hub soon,” I hope some of these charts and data will help them be more realistic.

Even better for India would be to help bring new pieces of the puzzle and/or boost existing pieces to levels that can take the country to a non-trivial percentage on the global semiconductor manufacturing industry map.

Arun Mampazhy has a BTech from IITM and MS from University of Maryland in semiconductor fabrication and over a decade of industry experience. His dreams of seeing a commercial fab takeoff in India has changed from black and white to colour over two decades. He can be reached via email nanoarun(at)gmail(dot)com or @nano_arun on twitter. Views expressed are personal.