Business

India Loses Nearly 10 Per Cent Of Foodgrains Post Harvest Due To Poor Storage. It Will Change With This Project

M R Subramani

Jan 14, 2020, 05:12 PM | Updated 05:12 PM IST

Save & read from anywhere!

Bookmark stories for easy access on any device or the Swarajya app.

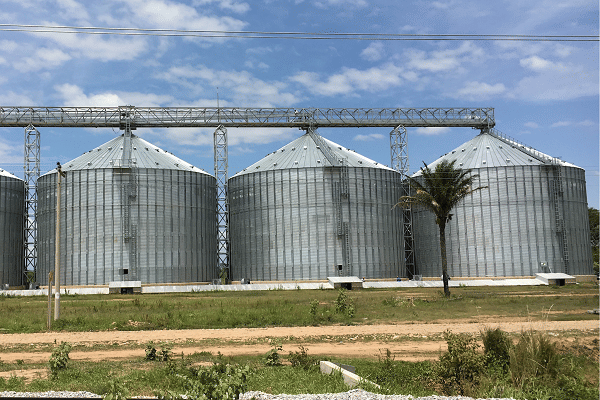

In its second term, the Narendra Modi government has expedited efforts to set up steel silos to store wheat as part of its initiatives to prevent wastage of foodgrains.

More importantly, the government is now all set to launch a pilot project to store rice in silos by the year-end.

The setting up of silos to store foodgrains such as wheat and rice is important as it helps in avoiding post-harvest losses and wastage during storage.

According to Indian Grain Storage Management and Research Institute (IGSMRI), post-harvest losses account for 10 per cent of total foodgrains.

The annual storage losses has been estimated at Rs 7,000 crore with insects alone accounting for Rs 1,300 crore wastage. Post-harvest losses have been brought down considerably since 2014, thanks to various initiatives launched by the Centre.

The setting up of the silos will remain a key element of scientific storage that will prevent losses and wastage. It assumes significance as wheat stocks with the Food Corporation of India (FCI) have bulged to 32.79 million tonnes (mt) against the mandatory stock norm of 13.8 mt as on 1 January.

Rice stocks, too, are far above the mandatory norm of 7.6 mt. FCI has 23.71 mt of rice stocks besides 27.88 mt of unmilled paddy in its warehouses.

Until now, the storage system of the Food Corporation of India (FCI) which maintains the buffer stocks to meet any food emergency and procures grains for distribution through ration shops, used the age-old traditional godowns and covered and plinth (CAP) system.

There were two problems with it. One, such storage led to wastage due to pest and rodent attack, pilferage and weather-related problems, mainly during the rainy season.

Two, grains that come to the warehouses first don’t usually go out first as the jute bags in which they are stored get caught at the bottom — in short, the first in, last out concept. Thus, over a period of time, these grains begin to rot.

It was with these issues in mind that the Atal Bihari Vajpayee government came up with the pilot project.

A silo system of storage helps preserve the grain in a controlled atmosphere — preventing losses due to insects or weather or rodents — apart from ensuring the stocks are despatched on a “first-in-first-out” basis.

Under the pilot project, silos were set up to store 0.55 mt of wheat in Punjab, Haryana, Karnataka, Maharashtra, Tamil Nadu and West Bengal.

In the case of Punjab, the private agency that set up the silo also got permission to directly procure from farmers.

The United Progressive Alliance (UPA) government under Manmohan Singh completed the pilot project but failed to act beyond that.

According to Vasudeva Munishwar, an expert in post-harvest management who runs Lotus Harvestec and was involved in the pilot project, there was 40 per cent savings in storage losses.

The silo project was dusted off the shelves after the National Democratic Alliance (NDA) government came back to power under Modi in 2014. The Union government decided to press ahead with modernisation of foodgrains storage.

Things have gathered further momentum now. Though the implementation of the silo project is lagging behind by a year, Munishwar says by the end of next year, India could have a capacity to store 10 mt of wheat in silos. This will include the initiatives taken by the state governments and private sector.

According to an FCI note, the government had set up a target to set up 0.5 mt in 2016-17, 1.5 mt in 2017-18, three mt in 2018-19 and five mt during the current fiscal.

“I would say there is a delay of one year in executing the silo projects,” said Sanjay Kaul, Managing Director and Chief Executive Officer, National Collateral Management Services Ltd (NCMSL).

NCMSL, now under Prem Watsa-led Fairfax Group, has won tenders to set up the steel silos at 16 places with a total capacity of 0.8 mt. It has executed the silo projects in Bareilly in Uttar Pradesh and Purnea in Bihar with a capacity of 50,000 tonnes each.

FCI said in its note that the target has been achieved mostly with regard to selection of silo operators, while only a 25,000 tonnes capacity has come up.

Kaul said the delay in setting up the silos was due to finding a suitable site for the storage.

“The silos can be set up only with rail terminal facilities. This can be done by going for a siding near a railway station. We cannot set up a silo in the middle of two stations,” Kaul said while explaining the problems faced by the firms that have won the tenders to construct the silos.

The companies will have to find suitable land that can accommodate the storage complex and the siding. This will have to get environmental and railway clearances, which are taking time.

On the other hand, a parcel of land near the railway station is costlier than lands elsewhere, thus adding to the costs. For example, if the cost to set up a silo without a rail terminal facility is Rs 30 crore, the cost of a silo with rail terminal is almost double.

States are constructing silos without rail terminal facilities if the initiative comes from them.

Munishwar said companies are facing problems in getting finance.

“Banks have tightened up their lending. Companies have to offer proper collateral for availing of loans. What was earlier possible with a phone call now requires much more ground work,” he said.

But the whole foodgrain sector has realised the utility of having steel silo storages on the lines that private companies such as ITC have come up with, especially for their maize (corn).

In addition, horizontal storages are being viewed for increasing capacity by utilising the vertical spaces. Storage at such sites can be doubled, says Munishwar.

With its pilot project to store rice in steel silos completed, neighbouring Bangladesh will likely begin setting up such storages later this year.

On the other hand, the Indian government has acknowledged the need for such storages in the country for rice.

According to Munishwar, the pilot project of silos for rice will come up at Buxar and Kaimur in Bihar with a total capacity of 25,000 tonnes.

Storing rice in silos needs a different technology, but it has been found to be beneficial, Munishwar said.

M.R. Subramani is Executive Editor, Swarajya. He tweets @mrsubramani